What is a timing belt, and what does it do?

You may have heard that car engines need three things to run: fuel, an ignition source, and sufficient cylinder compression. However, for an engine to work efficiently, it needs one more thing. This is the triple requirement that fuel, an ignition source, and sufficient cylinder compression are all available at the right moment.

On some engines, cylinder compression is managed by a timing belt. On other engines, both cylinder compression and the timing of the ignition source are managed by a timing belt. Therefore, the timing belt is a critically important component in the overall engine management system on both types of engines.

So if you had ever wondered what timing belts are, how they work, and why they fail, this guide will answer all your questions, starting with this one-

What is a timing belt?

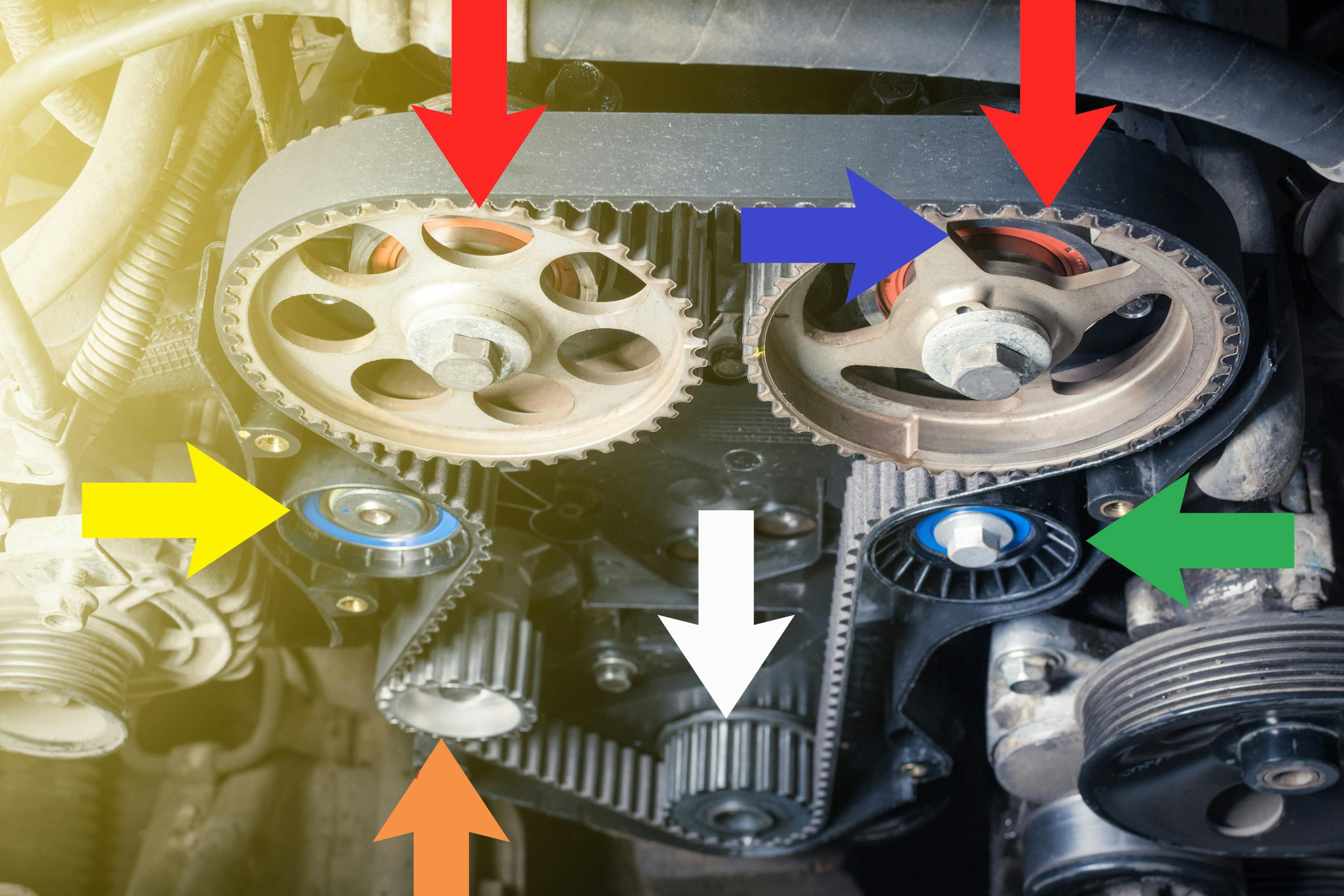

This image shows a typical timing belt installation on a twin camshaft engine. However, before we get to specifics let us look at what the coloured arrows in this image mean-

- The blue arrow indicates the engine’s direction of rotation

- The two red arrows indicate the intake and exhaust camshaft’s sprockets

- The green arrow indicates the timing belt’s drive side idler pulley

- The white arrow indicates the drive sprocket, which is mounted on the front end of the crankshaft

- The orange arrow indicates the sprocket on the water pump, which is driven by the timing belt. In this example, the water pump serves as a tensioning device, since the pump’s casing can be rotated in the engine block to adjust the timing belt’s tension

- The yellow arrow indicates the timing belt’s return side idler pulley.

NOTE: Idler pulleys have the same two functions on all engines. The first function is to route the timing belt so that more teeth are in contact with sprockets. The second function is to decrease the distance between the drive and driven sprockets to help maintain the belt's tension. Note that while there only two idler pulleys in this example, the timing belts on some V-type engines can have four or more idler pulleys.

Now that we can identify the main parts of a timing belt installation, we need to discuss the question of-

What do timing belts do, exactly?

The short answer is that a correctly installed timing belt regulates the timing of the engine valves. The longer answer is a bit more complex because cylinder compression is a critical factor for the complete combustion of air/fuel mixtures.

As a practical matter, cylinder compression is created by three things, these things being-

- The quality of the seal between the piston rings and the cylinder walls in the engine block

- The quality of the seal between the valve seats and the valve heads in the cylinder head

- The precision of the moments that both the intake and exhaust valves are closed

As far as timing belts are concerned, the last point is the most important. This is because the function of a timing belt is to regulate the opening and closing of the engine valves.

Think of a timing belt like this- since it has teeth that mesh with the teeth in the sprockets, the belt works like a continuous gear. Therefore, if the belt is installed and tensioned correctly, it must transmit the crankshafts’ rotation to the camshaft sprockets via the teeth on both the belt and the sprockets.

As a practical matter, the regulation of the engine valves is also known as "valve timing". Since the correct timing of the valves is critically important for efficient engine operation, timing belts are designed to have relatively long service lives. Thus, unless a timing belt fails prematurely, it will manage the valve timing reliably for several years.