What Happens if a PCV Valve Fails?

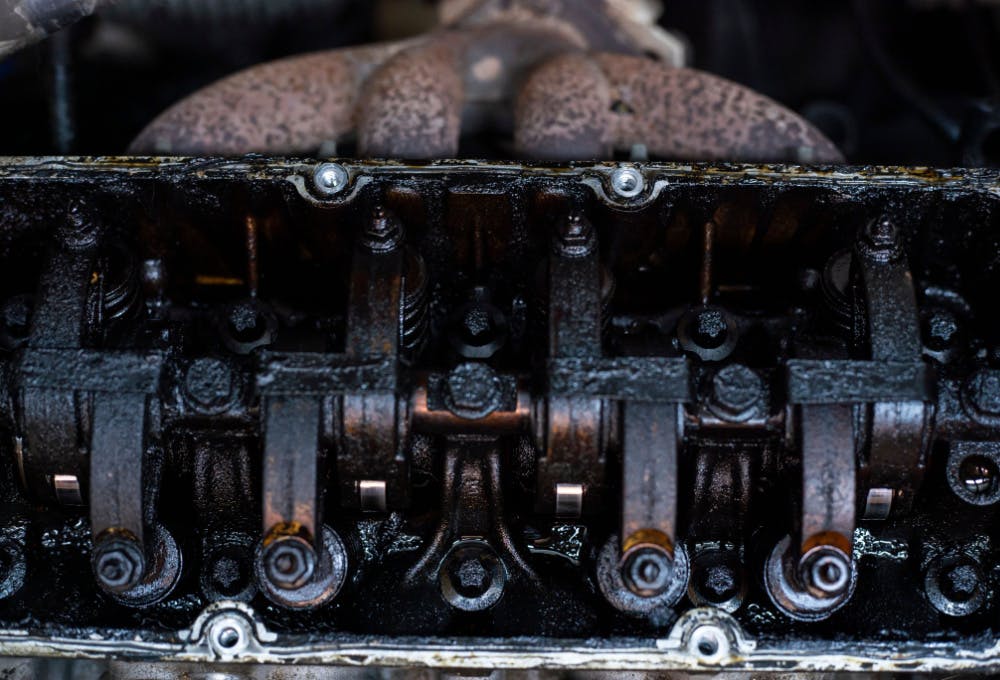

The effects or symptoms of a failed or failing PCV valve can be serious, such as in this example of carbon build-up in an engine caused by defective PCV valve, but in some cases, there may be no noticeable symptoms or even drivability issues present.

Nonetheless, since PCV valves often have a direct bearing on engine operation, much of what happens when a PCV valve fails depends on the engine, as well as on the nature of the failure. For the most part, though, PCV valves fail in one of two ways- a valve can become stuck in the open position, or it can become stuck in the closed position, with each type of failure producing distinctly different symptoms. Let us look at each type of failure in turn, starting with-

PCV valves stuck open

Since all PCV valves are calibrated to only allow a predetermined volume of gas to flow through them, a PCV valve that is stuck in the fully open position can directly influence the way the engine “breathes”.

In this regard, it is important to understand that the engine and fuel management systems do not monitor the vacuum in the engine directly. However, the air and volatile gases that enter the engine via the PCV valve and larger crankcase ventilation are included in the calculations these systems make to determine the most ideal air/fuel mixture for any given set of engine operating conditions.

As a practical matter, engine and fuel management systems monitor the volume of air that enters the intake system with a MAF (Mass Airflow) sensor, or a MAP (Manifold Absolute Pressure) sensor (and sometimes both a MAF and MAP sensor). Thus, if a stuck-open PCV valve allows an unlimited volume of air into the engine, the engine management system has to make large adjustments to the amount of fuel the injectors inject into the cylinders, but the problem with this is that this ability to compensate for unmetered air entering the engine is rather limited.

Therefore, in practice, the air/fuel mixture can contain too much air relative to the amount of fuel the injectors can deliver. This condition means that an engine can experience fuel starvation under some operating conditions, which can produce the following symptoms on many engines but note that not all of the symptoms listed below will always be present on all engines-

- Rough or erratic idling

- Misfires on multiple, or all cylinders at some or all engine speeds and loads

- Multiple fuel trim-related trouble codes may be present

- The engine may exhibit a noticeable loss of power at some or all engine speeds

- Fuel consumption may increase

- Oil consumption may increase

PCV valve stuck closed

Since it is the job of PCV valves to allow for the evacuation of waste gases from the engine, a PCV valve that is stuck in the closed position can have dramatic consequences, including the following-

- Oil seals can be pushed out of their housings as a result of the pressure build-up in the engine, which if it happens, always causes an immediate loss of significant amounts of engine oil

- The dipstick can be blown out of its tube, which is usually accompanied by clouds of oil droplets blowing out of the tube as the pressure in the engine is relieved

- The stuck-closed PCV valve can be blown out of the valve cover, which is usually also followed by clouds of oil droplets being ejected from the hole

- Somewhat counterintuitively, the engine's oil consumption may increase dramatically

- Some engines, most notably BMW engines, require a precise vacuum to be present in the engine to operate optimally. Thus, even if the PCV valve on these engines is stuck just partially closed, the resulting abnormal vacuum can cause( among other symptoms), misfiring, erratic idling, increased oil and fuel consumption, and reduced performance

Note that as a rule of thumb, PCV valves fail for very few reasons, but chief among these reasons is an excessive build-up of carbon and sticky oil residues inside the valve. Thus, the most effective way of preventing PCV valve failures is replacing the valve at regular intervals, such as at least once a year on engines that have naturally high rates of oil consumption, which is a common feature of many engines that are made in Germany.