What are camshafts and why are they needed?

Although camshafts are easy to locate in most engines, as in this example of two overhead camshafts, the operation, function, and properties of camshafts are often unclear, if not somewhat mysterious to many car owners who are not professional mechanics, or mechanically inclined.

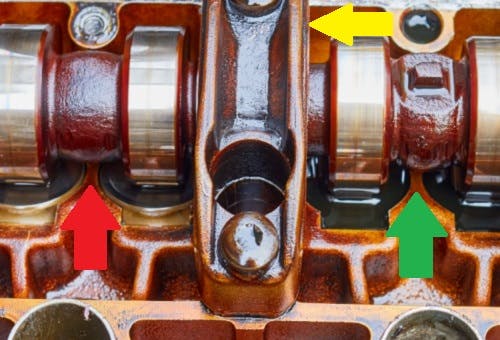

In its simplest form, a camshaft is just a long rotating shaft that is shaped to have lobes that act on the valves as the shaft rotates. This image shows some detail of camshaft lobes acting directly on valves via components known as “cam followers”, but let us look at what the arrows in this image mean-

- The yellow arrow shows one of the several bearing caps that prevent the camshaft from buckling or bending under the force of the valve springs (not shown here) when the cam lobes compress the valve springs

- The cam followers are the small cylindrical components shown here on either side of the red and green arrows. Note that in this particular example, the two cam lobes to the left of the bearing cap act on two valves on one cylinder, while the two cam lobes to the right of the bearing cap act on two valves on an adjacent cylinder

- The cam followers are the small cylindrical components shown here on either side of the red and green arrows. Note that in this particular example, the two cam lobes to the left of the bearing cap act on two valves on one cylinder, while the two cam lobes to the right of the bearing cap act on two valves on an adjacent cylinder

For this discussion, it is irrelevant whether the two valves on each cylinder shown here are intake or exhaust valves. What is important though, is the height of the tops of the cam followers under each cam lobe. The two cam followers on the left (red arrow) are protruding above the surface of the cylinder head, and although the profiles of the cam lobes on the right are not apparent in this view, the cam lobes on the right (green arrow) are pushing the cam followers below the surface of the cylinder head.

In this example, the position of the cam lobes means that the valves in the cylinder on the left are closed or closing, while the valves on the right are open, or opening. The distance by which the cam lobes push the valves down depends on the height of the cam lobes, while the profile of the cam lobe determines the valve duration, which engine designers measure in degrees of camshaft rotation. Although valve duration differs between engines and camshaft designs, valve duration begins when the valve starts to open, and ends when the valve closes on all engines.

So, regardless of the height and profile design specifics of any given camshaft, all camshafts have the task of regulating the opening and closing of the valves relative to the positions of the pistons in the cylinders. Thus, no four-stroke engine can run without a mechanism that regulates the opening and closing of the valves according to the order in which combustion occurs in each cylinder.

Note though, that for any camshaft to regulate the valves on any engine effectively and correctly, the camshaft must be referenced or indexed to various reference points, but since this is a hugely technical topic, the finer points of camshaft phasing/crankshaft correlation (aka valve timing) fall outside the scope of this article.

Nonetheless, suffice it to say that camshafts are critical components that control a major aspect of how well (or otherwise) any four-stroke internal combustion engine runs, regardless of whether that engine is in a supercar, a sedate urban runabout, or in an enormous marine or locomotive engine. In all cases, the correct regulation of the engine's valves is critically important if a four-stroke engine is to operate at peak efficiency.

Note that two-stroke engines do not need camshafts and their associated moving parts and components like valves, valve springs, and rocker arms because the operating principles of two-stroke engines are vastly different from those of four-stroke engines.