How much does it cost to repair a crankshaft?

A simple repair on a crankshaft for a four-cylinder engine that only involves polishing all the journals can cost as little as $100, depending on your location. However, a major repair on that same crankshaft that involves welding, grinding, stress relieving, balancing, and testing for cracks can cost anything between several hundred dollars and a thousand dollars or more, depending on both your location and the vehicle's make and model.

Having said though, there are far too many variables involved with crankshaft repair to provide even a broad range of price estimates that will cover all or even most situations. In practice, the final cost will always depend on factors that (at a minimum) include the following-

- Whether the crankshaft had already been removed from the engine; if your chosen engine repairer has to remove the crankshaft from the engine, this could add an additional several hundred dollars to the final cost

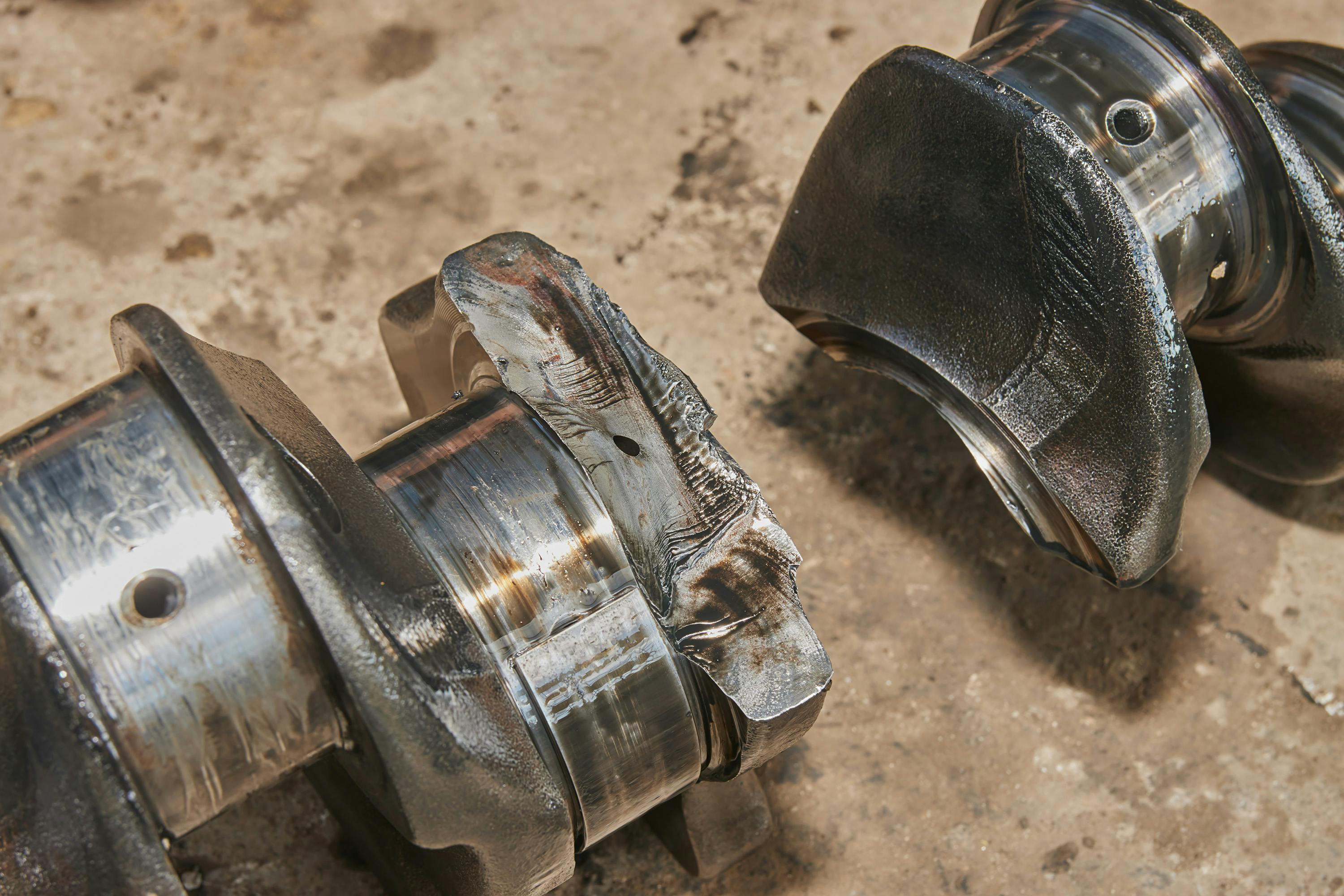

- The degree of damage to the crankshaft, but be aware that cracked crankshafts cannot and should not be repaired because such a "repair" can never restore the rigidity and tensile strength of a crankshaft

- Whether the bearing journal diameters can accommodate the repair

- Whether the crankshaft can be repaired or repaired cost-effectively often depends on the steel alloy the crankshaft is made from. Note that crankshafts made from some steel alloys cannot be repaired cost-effectively, even if the damage to the crankshaft is relatively minor

Note also that even if only one or two big-end journals are damaged, all the big-end journals will be machined to the same diameter to preserve the crankshaft’s inherent balance. Since this also applies to main bearing journals, the final cost of the repair will be based on the number of cylinders in the engine, and/ or the number of main bearing journals in the crankshaft, regardless of the number of journals that are actually damaged.

As a final thought, it should be remembered that crankshaft repairs are seldom done in isolation. Crankshaft repairs are typically just one component of the total cost of a major engine overhaul or rebuild, meaning that the cost of the crankshaft repair on its own should be weight against the other costs involved in rebuilding an engine.

For example, if you are rebuilding a supercar engine, the eye-watering cost of repairing the crankshaft might be justifiable. However, if you are rebuilding a 50-year-old big-block V8 engine from the classic muscle car era, spending one thousand dollars (or more) just on repairing the crankshaft might be hard to justify, since new crankshafts for these engines are (almost) freely available for only a few hundred dollars.

Thus, all things considered, we recommend that you discuss your particular needs and requirements with an expert engine rebuilder before you commit yourself to a crankshaft repair because the final repair costs could be much higher than you anticipated or are willing to spend.