How do I know my crankshaft is damaged or defective?

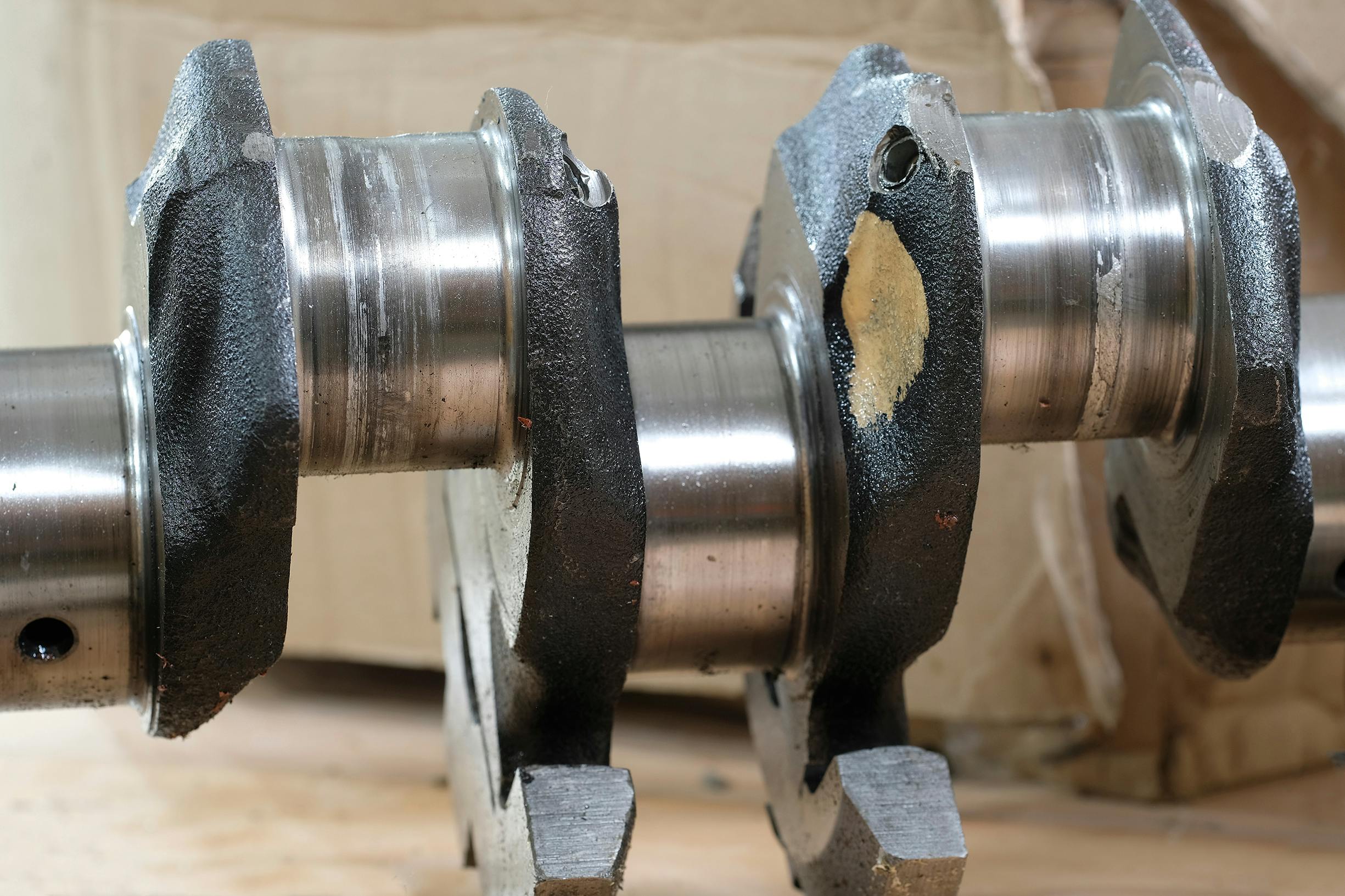

Many people might see the discolouration on these two adjacent big-end bearing journals as just that, a bit of discolouration, but the fact is that this crankshaft is severely damaged as a result of poor lubrication, and is, therefore, unsuitable for re-use in its current condition.

In this example, the grey-ish discolouration is actually material that had been transferred from the bearing insert that had become welded to the bearing journal surface, while the bluish rings/streaks are evidence of severe overheating of the bearing journals’ surfaces. However, observant readers might wonder why it is that if this crankshaft suffered damage as the result of poor lubrication, the main bearing journals appear to be undamaged. Shouldn’t all bearing journals be damaged equally? Well, not necessarily, and here is why this type of “selective” damage is common-

In this particular example, the flow of lubrication oil had not been cut off completely, as evidenced by the fact that the big-end bearing inserts had not seized onto the bearing surfaces over their whole width. Moreover, since main bearing journals usually have bigger diameters (as shown in this example) than big-end journals, main bearing inserts/journals a) hold more oil in their interfaces than big-end bearing insert/journal interfaces do, and b), main bearings do not experience quite the same shock loads that big-end bearings/journals do.

Additionally, the bigger surface areas of main bearings are better able to withstand extreme pressures and mechanical wear (even with reduced lubrication) because the loads on them are spread out over a larger area, meaning that main bearings are not loaded as heavily as big-end bearings are. Finally, main bearings are always the first components to receive pressurised engine oil, while the oil for the big-end bearing has to travel some distance through the crankshaft to reach the big-end bearing/journal interface(s).

The practical effect of all of the above is this: even if the oil supply to the crankshaft is restricted (as opposed to being cut off completely) for whatever reason, the available supply of oil is often sufficient to keep the main bearing properly lubricated for the reasons stated above. However, since the available oil supply is-

- typically (but not always) divided equally between the main bearings

- and, some oil pressure is lost through the main bearing journal/bearing insert clearances

the result is usually that there is an insufficient supply of oil available to keep some, or all of the big-end bearings lubricated. This is precisely what caused the damage to the big-end bearing journals of the example crankshaft shown above, and while this crankshaft is almost certainly repairable, a severely restricted or completely cut-off oil flow will typically damage a crankshaft to the point where it becomes irreparable by any means.