How do EGR Valves Work?

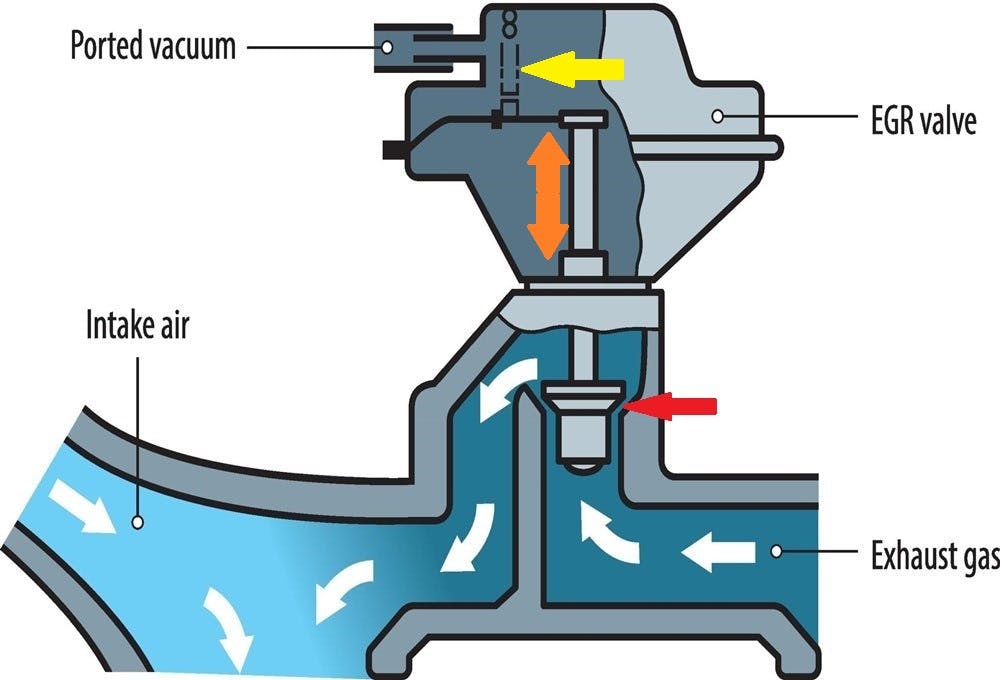

Although all exhaust gas recirculation valves perform the same function, which is to allow some exhaust gas to enter the engine as an emissions control measure, there are several types of EGR valves in common use today, with major differences between the design, and methods of operation and control between the main types of EGR valves.

For the most part, the biggest differences occur between EGR valves used on petrol engines and those used on diesel engines, but there are also significant design and functional differences between EGR valves used on each type of engine. Moreover, EGR valves are also calibrated differently, meaning that although any given EGR valve might fit on multiple engines, that valve will only work as expected on the engine it was calibrated for due to the airflow dynamics of different engines.

With the above said, it should be clear that while the above schematic diagram of the basic operating principles of EGR valves is representative of most, if not all EGR valves, EGR valves are application-specific, and are therefore not interchangeable between applications, even though any given two EGR valves might appear to be identical from the outside. So, with that in mind, let us look at the main types of EGR valves in common use today, starting with-

Diesel high-pressure EGR valves

Since diesel exhaust gas often contains both high amounts of solid diesel soot and significant amounts of vapourised engine oil, this type of EGR system diverts high-flow exhaust gas into the engine via the EGR valve before the exhaust gas enters the DPF (Diesel Particulate Filter) to prevent the soot and oil vapour from forming a sludge that can destroy the DPF.

In some designs, the exhaust gas flows into the intake manifold through the EGR valve, where it mixes with the intake air, while in other designs, the exhaust gas is introduced into the combustion chambers directly through small-diameter channels in the cylinder head(s). Note, though, that since diesel engines are typically un-throttled, diesel engines do not generate a sufficiently high intake manifold vacuum to help “draw” exhaust gas into the engine. To overcome this problem, high-flow EGR systems on diesel engines usually also employ a secondary valve that is connected to a fairly complex engine vacuum system to create a strong vacuum in the intake manifold.

It should be noted that while high-flow EGR systems are typically more efficient than low-flow EGR systems, the biggest disadvantage of high-flow systems is that oil and soot-laden exhaust gas can quickly clog both EGR valves, exhaust gas feed pipes, and exhaust flow channels in cylinder heads. The only way to clear clogged exhaust gas flow channels in cylinder heads is to remove the affected cylinder head(s) to attempt to clean out the channels. Note that the operative word here is "attempt" because there are no guarantees that these channels can be cleared out successfully, regardless of the methods employed.

Diesel low-pressure EGR valves

Low-pressure EGR systems divert exhaust gas that has already passed through the DPF to the engine via a long feed tube. The single biggest drawback of such systems is their low efficiency due to the long distance the exhaust gas has to travel before it reaches the engine.

However, the single biggest advantage low-pressure EGR systems have over high-pressure systems is that exhaust gas feed pipes/gas flow channels in cylinder heads, and EGR valves have greatly longer service lives because the exhaust gas that passes through them does not contain solid diesel soot particles.

EGR systems on petrol engines work in much the same way as high-pressure diesel EGR systems, but EGR valves on petrol engines come in two main types, these types being-

Vacuum-controlled EGR valves

These types of EGR valves use the engine vacuum to act on a diaphragm in a vacuum actuator to open the EGR valve, and the tension of a built-in spring to return the valve to its closed position. Depending on the application, the section of the engine vacuum system that controls the EGR valve can contain several vacuum-controlled solenoids and check valves that work together to modulate the movement of the EGR valve’s pintle as a means of improving control over the movement of the valve pintle.

Most vacuum-controlled EGR valves also contain a built-in position sensor to monitor the movement of the valve pintle, since ECUs cannot monitor the flow of exhaust gas into the engine directly. Thus, the position sensor is used to monitor the status (OPEN/CLOSED) of the EGR valve, so if the position sensor senses that the EGR valve is not fully closed, the ECU can infer the volume of exhaust gas that enters the engine at any given moment, based on the design of the EGR valve itself.

Electronically-controlled EGR valves

Electronic control of an EGR valve through either a solenoid or a stepper motor allows for a far higher level of control over the amount of exhaust gas that enters the engine than is possible to achieve with any other method of control.

Although electronic control of the EGR system adds a layer of complexity to the system that other control methods do not require, the advantage of electronically-controlled EGR systems is the fact that combustion temperatures can be controlled to always remain below the threshold at which oxides of nitrogen (NOx) forms. This not only greatly extends the useful lives of several major exhaust components, but also improves engine performance and fuel economy over the whole of the engine’s operating range.

NOTE: It is worth pointing out that although various exhaust gas recirculation technologies have collectively formed the proverbial backbone of primary exhaust after-treatment systems on both petrol and diesel engines for many years, VVT/VCT (Variable Valve Timing / Variable Camshaft Timing) technologies have largely supplanted EGR as a primary exhaust after treatment measure. This is because appropriate valve timing adjustments under some operating conditions have the same quenching effect on combustion temperatures as EGR. As such, vehicles with VVT/VCT systems do not have or need EGR systems.

Cooled EGR systems

Some of the latest iterations of EGR systems incorporate a heat exchanger that cools the hot exhaust gas significantly before it enters the engine.

The practical advantage of EGR coolers is that the cool exhaust gas does not contribute to the temperature of the air/fuel mixture during the compression stroke, thus reducing the possibility of the air/fuel mixture igniting prematurely in high-compression engines during high engine load conditions.