Everything you need to know about Wheel Alignment

Have you ever wondered why the tyres on your car are wearing out so fast? It might seem like they don't make tyres to last as long as they used to, so if you have to replace your tyres yet again, you might have a wheel alignment problem.

In this guide, we explain what wheel alignment is, why it is important, and how regular wheel alignment services can save you a ton of money over the life of your car. Let us start with answering this question-

What is a wheel alignment?

In its simplest form, a "wheel alignment" is the process of aligning a car's wheels. In practice, the wheels are aligned to each other, and relative to an imaginary line that runs lengthwise through the vehicle. This line is known as the “thrust line”, which is shown here by the blue arrow.

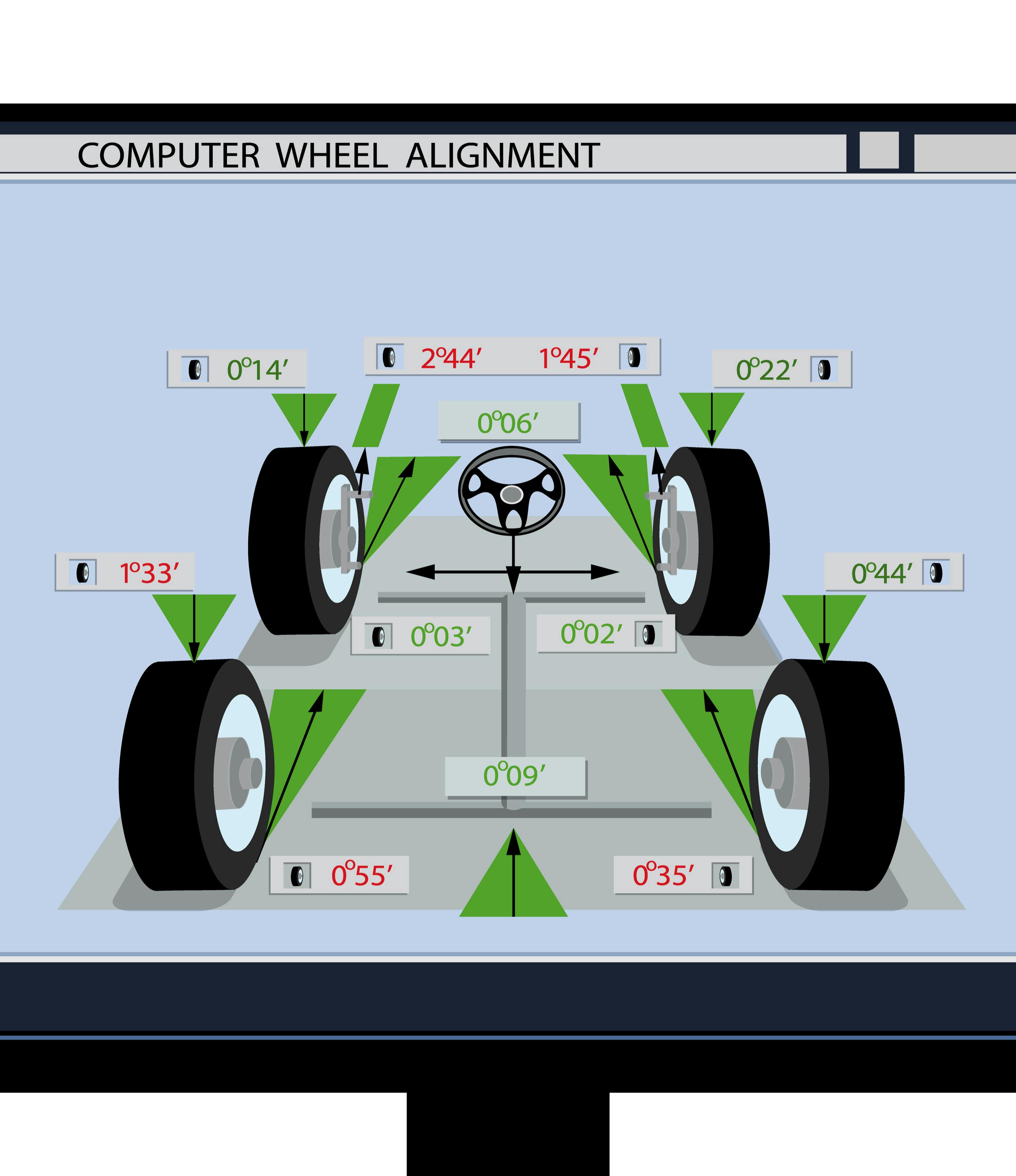

Before we get to the specifics of what the image above represents, we need to say that all cars have different wheel alignment specifications. This is because cars have different suspension designs and layouts, different weights, and different distances between their wheels and axles.

Therefore, when a car manufacturer designs a new model, they also calculate how the wheels will behave when the vehicle is driven. Based on this theoretical information, the manufacturer calculates wheel alignment specifications, such as shown in the example above. However, to understand how a wheel alignment affects a vehicle, we need to look at what the numbers in the above example mean.

The above example is what a wheel alignment sees on his computer screen when he starts a wheel alignment procedure. The values shown here only apply to this specific vehicle, so here is what they mean in this example-

The blue arrow

This is the vehicle’s thrust line. Both the wheels and the steering angle sensor are set to this line.

The green numbers

In this example, the green numbers show wheel alignment values that are within specifications for this vehicle. In this example, the camber of the front wheels, as well as the right rear wheel is within the manufacturer’s specifications.

The red numbers

The red number for the left rear wheel shows that the camber of this wheel is not within the manufacturer’s specifications.

The two red numbers at the top of the frame show that the toe-in/toe-out settings for the front wheels are not within specifications. Similarly, the two red numbers at the bottom of the frame show that the toe-in/toe-out settings for the rear wheels are also not within the manufacturer’s specifications.

The above is saying a lot, so let us explain some technical terms by answering these questions-

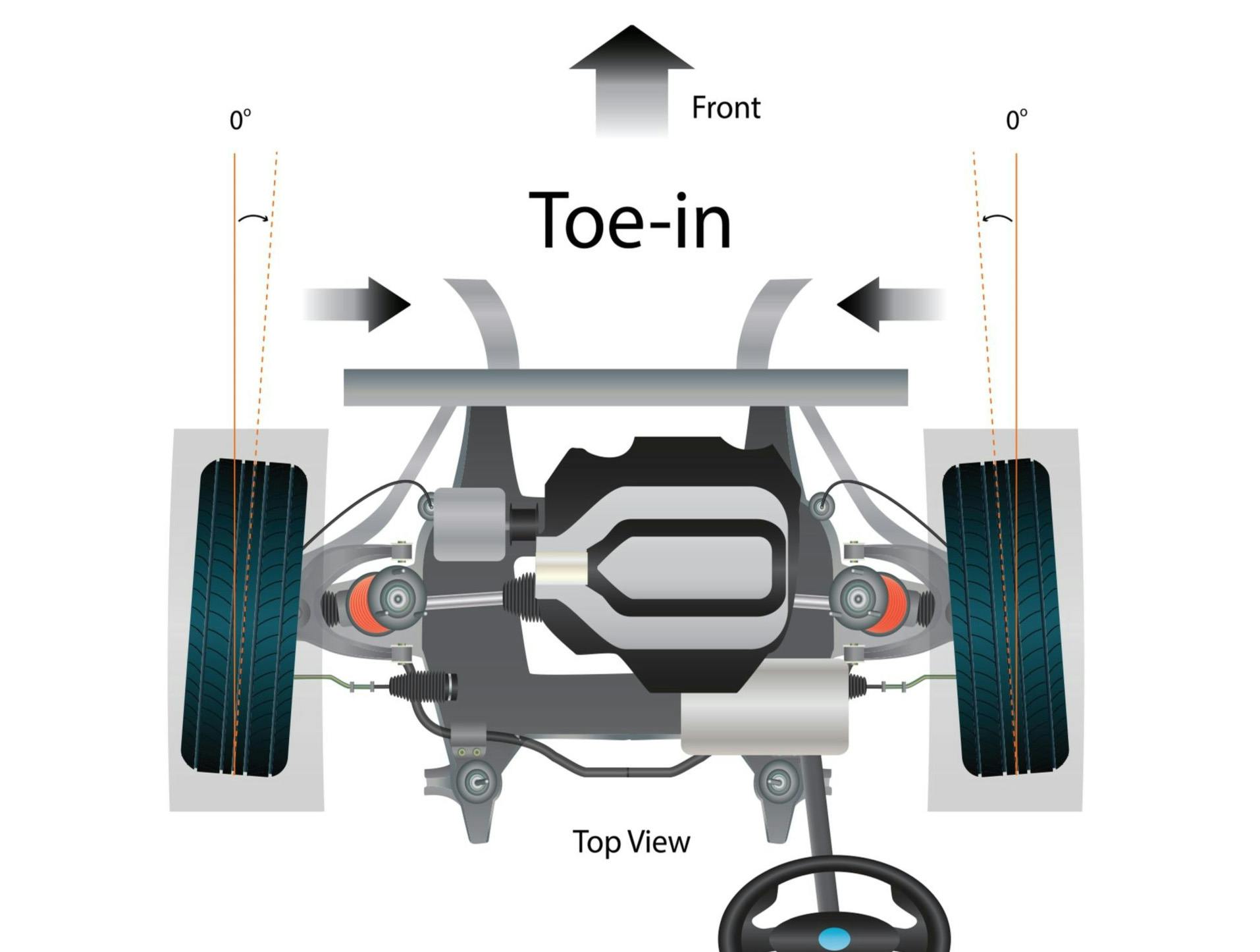

What is toe-in?

As seen from above, this example shows the front wheels of a vehicle in a toe-in condition. This means that the parts of the wheels in front of the axle are pointing towards each other.

In practice, the front wheels of light vehicles are not meant to point dead ahead. Depending on the vehicle, the front wheels can point inwards or outwards by a small amount. This helps with straight-line tracking, and to return the wheels automatically to the “dead ahead” position after turning.

The maximum allowable deviation from the dead-ahead position is specified by the car manufacturer. When this deviation is exceeded, the vehicle may become difficult to steer accurately.

What are the symptoms of excessive toe-in?

This image shows more wear on the outside edge of the tyre than on the inside edge. Note that this is an example of uneven tyre wear caused by a toe-in condition. The actual amount of uneven wear depends entirely on how much the toe-in setting deviates from specified values.

Apart from uneven and accelerated tyre wear, the usual symptoms of excessive toe-in conditions could include one or more of the following-

- The vehicle may “wander” across the road

- It may be difficult to maintain a straight-ahead direction

- The vehicle may pull to one side on roads that are not level

- Steering responses may be sluggish, or the steering may have a “spongy” feel

- The steering wheel may not return to the dead-ahead position automatically after turning

What causes toe-in conditions?

The main causes of toe-in conditions are largely similar on all light vehicles, and could include one or more of the following-

- Worn or damaged control arm bushings

- Damaged or worn steering system components

- Improper wheel adjustment settings made during previous wheel alignment procedures

- Structural damage to the vehicle caused by accidents, or hitting potholes as speed

- Colliding with kerbs during parking

Toe-in conditions on all vehicles can be adjusted during a wheel alignment procedure. However, all steering and suspension components must be free of excessive free-play or mechanical wear before this setting can be adjusted to the manufacturer’s specifications.

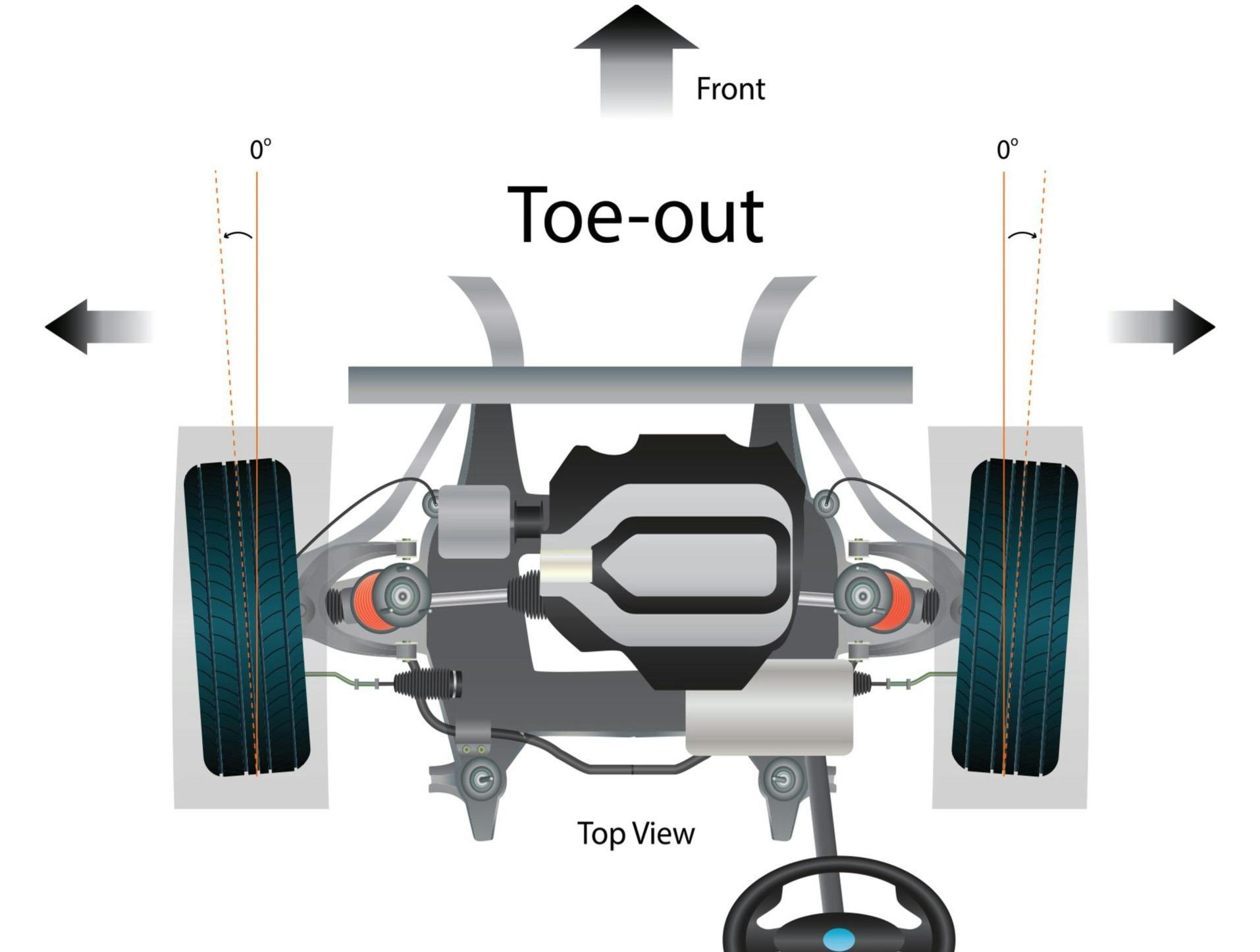

What is toe-out?

As seen from above, this example shows the front wheels of a vehicle in a toe-out condition. This means that the parts of the wheels in front of the axle are pointing away from each other.

In practice, the front wheels of light vehicles are not meant to point dead ahead. Depending on the vehicle, the front wheels can point inwards or outwards by a small amount. This helps with straight-line tracking, and to return the wheels automatically to the “dead ahead” position after turning.

The maximum allowable deviation from the dead-ahead position is specified by the car manufacturer. When this deviation is exceeded, the vehicle may become difficult to steer accurately.

What are the symptoms of excessive toe-out?

This image shows more wear on the inside edge of the tyre than on the outside edge. Note that this is an example of uneven tyre wear caused by a toe-out condition. The actual amount of uneven wear depends entirely on how much the toe-out setting deviates from specified values.

Other typical symptoms of excessive toe-out conditions could include one or more of the following-

- The vehicle may “wander” across the road

- It may be difficult to maintain a straight-ahead direction

- The vehicle may pull to one side on roads that are not level

- Steering responses may be sluggish, or the steering may have a “spongy” feel

- The steering wheel may not return to the dead-ahead position automatically after turning

What causes toe-out conditions?

The main causes of toe-out conditions are largely similar on all light vehicles, and could include one or more of the following-

- Worn or damaged control arm bushings

- Worn or damaged ball joints

- Worn or damaged tie-rod ends or other steering system components

- Improper wheel adjustment settings made during previous wheel alignment procedures

- Worn or damaged wheel bearings

- Structural damage to the vehicle caused by accidents, or hitting potholes at speed

- Colliding with kerbs during parking

Toe-out conditions on all vehicles can be adjusted during a wheel alignment procedure. However, all steering and suspension components must be free of excessive free-play or mechanical wear before this setting can be adjusted to the manufacturer's specifications.

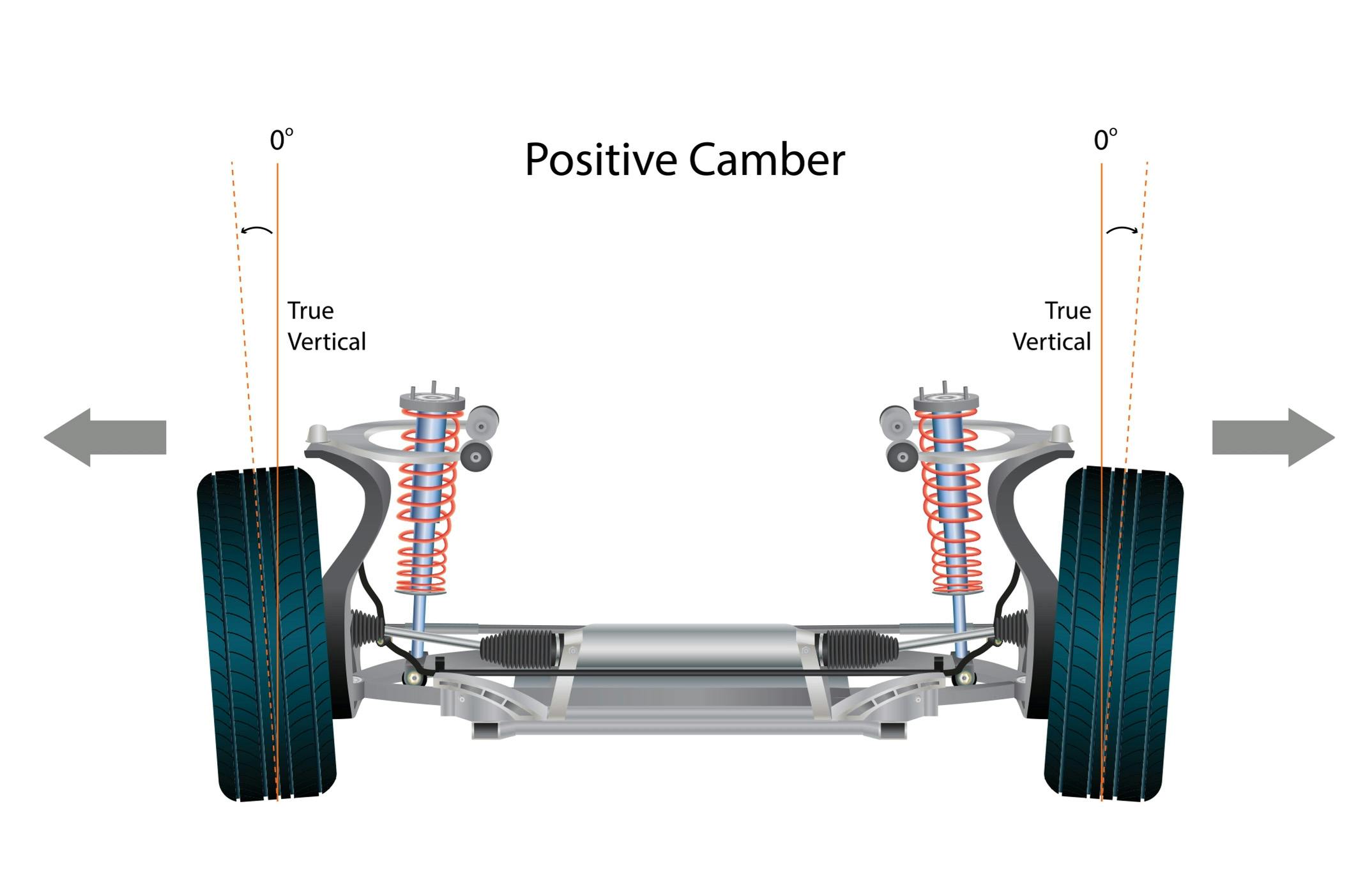

What is positive camber?

As seen from the front of the vehicle, this image shows a positive camber condition, which means that the tops of the wheels have an outward tilt..

In practice, the suspension systems of light vehicles are designed so that the front wheels are perpendicular to the ground when the wheels are pointing straight ahead and the vehicle is not carrying a load.

Depending on the vehicle, the front wheels can “lean” over from only one or two degrees, to as much as ten degrees when the wheels are fully turned to either direction. This helps to return the wheels automatically to the “dead ahead” position after turning. The maximum allowable deviation from the wheels’ vertical position is specified by the car manufacturer.

What are the symptoms of excessive positive camber?

This image shows an extreme amount of uneven tyre wear caused by an excessive positive camber condition. In this case, the accelerated wear is on the outside edge of the tyre. In cases of excessive negative camber, the accelerated wear will be on the inside edge of the tyre.

While uneven and accelerated tyre wear is the main symptom of excessive positive camber, other symptoms could include the following-

- The vehicle may “pull” to one side or the other

- The vehicle may “pull” to one side only under braking

- It may require more effort to steer the vehicle in one direction than the other

- The steering may have a spongy feeling, or the steering response may be slow or sluggish

- The steering wheel may not return to the dead-ahead position automatically after turning

What causes excessive positive camber?

Note that, unlike toe-in/toe-out conditions that usually affect both front wheels, positive or negative camber can affect only one wheel. Whether one or both wheels on an axle is affected depends on the cause of the problem, which could include the following-

- Structural damage to the vehicle caused by accidents or hitting potholes at speed

- Fitment of incorrect suspension parts such a ball joints, and/or control arms

- Incorrect fitment of control arm bushings on some vehicles

- Improper setting of the camber angle on vehicles that allow adjustment of the camber angle

- Improper setting of the camber angle during previous wheel alignment procedures

Note that with a few exceptions, the camber angle on the front wheels of passenger vehicles is fixed, and cannot be adjusted. However, camber angles are usually adjustable on vehicles such as pick-up trucks that have upper and lower control arms in their front suspensions.

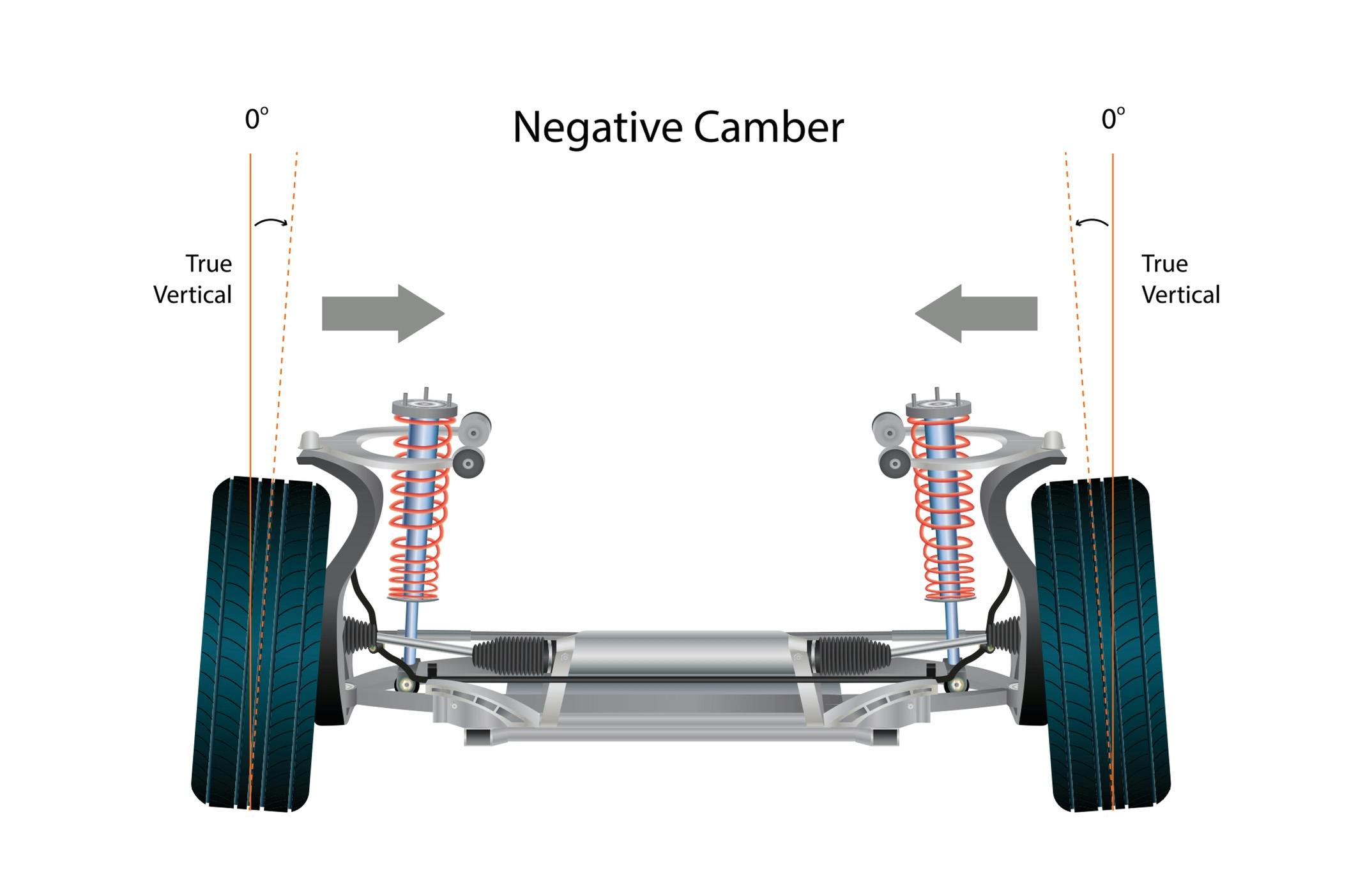

What is negative camber?

As seen from the front of the vehicle, this image shows a negative camber condition. This means that the tops of the wheels are pointing towards each other.

In practice, the suspension systems of light vehicles are designed so that the front wheels are only vertical (upright) when the wheels are pointing straight ahead and the vehicle is not carrying a load.

Depending on the vehicle, the front wheels can “lean” over from only one or two degrees, to as much as ten degrees when the wheels are fully turned in either direction. This helps to return the wheels automatically to the “dead ahead” position after turning. The maximum allowable deviation from the wheels’ vertical position is specified by the car manufacturer.

What are the symptoms of excessive negative camber?

This image shows an extreme amount of uneven tyre wear caused by an excessive negative camber condition. In this case, the accelerated wear is on the inside edge of the tyre. In cases of excessive positive camber, the accelerated wear will be on the outside edge of the tyre.

Extremely uneven and accelerated wear of the tyre is the main symptom of excessive negative camber. However, other typical symptoms could include one or more of the following-

- The vehicle may “pull” to one side or the other

- The vehicle may “pull” to one side only under braking

- It may require more effort to steer the vehicle in one direction than the other

- The steering may have a spongy feeling, or the steering response may be slow or sluggish

- Unless the front wheels are perpendicular to the ground, the steering wheel may not return to the dead-ahead position automatically after turning

What causes excessive negative camber?

Note that, unlike toe-in/toe-out conditions that usually affect both front wheels, positive or negative camber can affect only one wheel. Whether one or both wheels on an axle is affected depends on the cause of the problem, which could include the following-

- Structural damage to the vehicle caused by accidents or hitting potholes at high speed

- Damaged or worn wheel bearings that affect the wheel’s camber

- Damaged or worn parts (such as ball joints) in the vehicle’s suspension

- Damaged or worn control arm bushings

- Fitment of incorrect suspension parts such a ball joints, and/or control arms

- Incorrect fitment of control arm bushings on some vehicles

- Improper setting of the camber angle on vehicles that allow adjustment of the camber angle

- Improper setting of the camber angle during previous wheel alignment procedures

Note that with a few exceptions, the camber angle on the front wheels of passenger vehicles is fixed, and cannot be adjusted.As a result, the front wheels are always perpendicular to the ground in the dead-ahead position.

However, camber angles are usually adjustable on vehicles such as pick-up trucks that have upper and lower control arms in their front suspension systems.

Do front-wheel-drive vehicles need 4-wheel alignment?

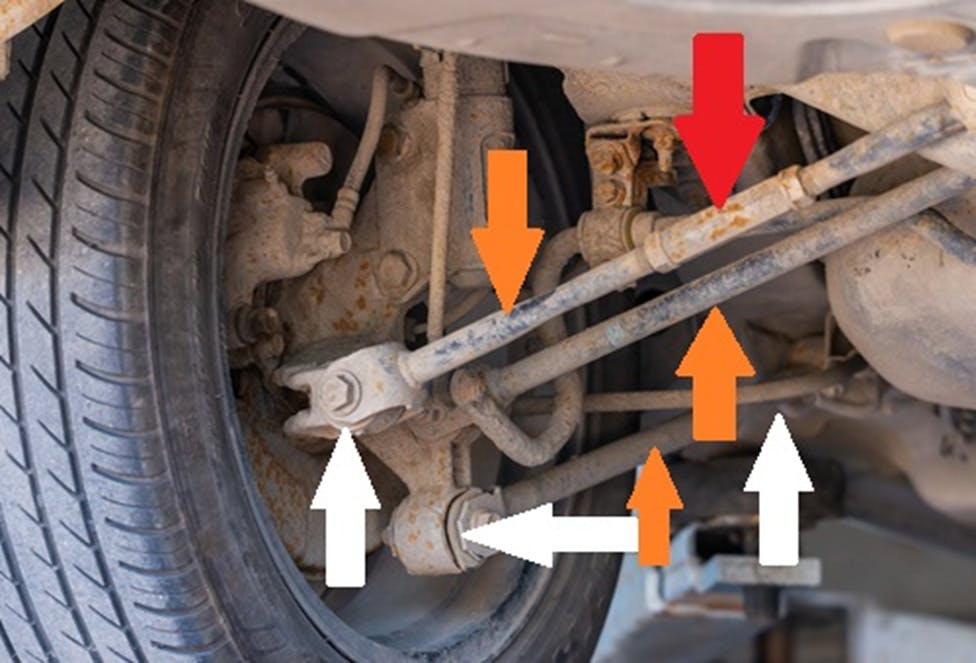

The short answer is yes, FWD cars need 4-wheel alignments. In fact, it is impossible to align the front wheels on a FWD drive vehicle without verifying that the rear wheels are aligned properly. Let us take a closer look at the above picture of a typical rear suspension design on a FWD car.

Here is what the arrows in this image of the left-hand rear suspension mean-

Red arrow

This is the adjustment point a technician would use to adjust the toe-in/toe-out of the left rear wheel. The right rear wheel has a similar adjustment point.

White arrows

These show attachment points that all contain rubber bushings. While all rubber bushings allow for movement of the suspension, the main function of these rubber bushings is to absorb vibrations.

Orange arrows

These show the control arms that attach the wheel to the vehicle. Under normal operating conditions, these control arms will last as long as the vehicle, but striking potholes, or colliding with kerbs during parking manoeuvres can cause them to bend.

Depending on which control arm is damaged, the affected wheel can develop excessive toe-out, or excessive toe-in, or an excessive inward or outward tilt. Note that in these cases, the problem cannot be “adjusted out”. The only way to fix rear wheel alignment issues caused by damaged rear control arms is the replacement of the damaged parts. Note that rear wheel drive vehicles are largely immune to rear-wheel misalignment issues.

Moreover, damaged or worn rear wheel bearings can cause toe-out and/or camber issues that can only be fixed by replacing the damaged wheel bearing(s).

How are wheel alignments done?

When a car is placed on the alignment rack, the technician places an alignment target on each wheel. Then the technician enters the vehicle’s make and model into a computer that measures the actual wheel alignment to determine the dead-ahead position of the front wheels.

The technician will then place the front wheels in the dead ahead position as identified by the computer before locking the steering wheel in place with a special clamp.

Most wheel alignment systems use reflected light beams to measure the actual positions of the wheels relative to each other. Depending on the readings displayed by the system, as shown here, the technician will then make appropriate adjustments to each wheel as required.

The purpose of the adjustments is to reset each wheel so that the toe-in/toe-out reading falls within the manufacturer’s specifications. In cases where camber adjustment is possible, the technician will make the required adjustments to bring the camber setting to within acceptable limits.

However, before making any adjustments, the technician will inspect the steering and suspension systems to identify worn, damaged, or broken parts. Since broken or worn parts directly affect the wheel alignment, and by extension, the vehicle’s steering axis,the technician will recommend that defective parts be replaced before adjusting the wheel alignment.

Note that it might be impossible to perform a proper wheel alignment when a technician finds one or more of the following issues on a vehicle-

- Worn or damaged wheel bearings

- Worn or damaged ball joints

- Worn or damaged steering racks or steering boxes

- Worn or damaged Steering drag links and/or idler arms

- Worn or damaged tie-rod ends

- Worn or damaged steering rack ends

- Worn, damaged, or broken control arm bushings

- Worn or damaged tyres

- Worn or damaged McPherson strut mountings

- Worn or damaged shackle bushings on cars with solid rear axles

- Worn or damaged shock absorbers that affect a car’s ride height

- Worn or damaged torsion springs on pick-up trucks that affect the vehicle’s ride height

It is rare for all of the above issues to be present on the same car at the same time. However, any one of the above issues could make it impossible to perform a proper wheel alignment procedure on any vehicle. This is because worn or damaged parts cause excessive free play in the steering and/or suspension systems that cannot be compensated for by wheel alignment adjustments.

Other issues that could make it very difficult, if not always impossible to perform a wheel alignment procedure could include the following, even if all parts are new-

- Suspension kits that raise or lower the vehicle’s ride height. These kinds of modifications often change the geometry of a suspension system, and in some cases, it can take a lot of trial and error to set the wheel alignment to acceptable values

- The use of non-standard tyre/rim combinations can create abnormal rolling resistance, which can directly affect the wheel alignment

- Making large changes in a vehicle’s weight distribution, such as fitting a large, non-standard engine into a passenger vehicle. This can change the way a suspension system haves under load, which means that the manufacturer’s wheel alignment settings may not apply to the vehicle

Based on the above, it should be clear that wheel alignments cannot be performed on a DIY basis. In fact, the only way to have a wheel alignment done is to have it done by qualified technicians that have access to factory service information and calibrated equipment.

Therefore, we highly recommend that you Find a Mechanic on Mechanic.com.au to find suitably qualified and professional wheel alignment technicians near you.

How often should I have my car’s wheels aligned?

Although wheel alignment is an important part of maintaining a car, wheel alignment and balancing of tyres are usually not included as mandatory items in a vehicle’s maintenance schedule. Nonetheless, since tyres like the one shown above can no longer be saved by a wheel alignment or a tyre rotation, we recommend that you have the wheel alignment on your car checked every time you-

- Service your car

- When you rotate your tyres

- Replace one or more tyres

- Notice one or more tyres wearing unevenly

- When you notice anything different about how your car handles. This could include things like the steering becoming sluggish, or the vehicle pulling to one side under braking

Apart from the above, getting a regular wheel alignment service done is always a good idea, because-

You can save on fuel

All vehicles have something called a “rolling resistance”, which is the amount of friction that is present between the tyres and the road surface. When the tyres are properly aligned and inflated correctly, this amount of friction is relatively small, because the wheels simply roll along with the vehicle.

However, if the wheels are not aligned, the wheels do not rotate freely, even if the tyres are inflated to the correct pressures. In practice, misaligned wheels are “dragged” across the road, which greatly increases the wheel’s rolling resistance. Therefore, you need more fuel to overcome the additional friction.

By keeping the wheels both aligned and inflated correctly, you can increase a vehicle's fuel efficiency by as much as 6%, or more.

You extend the lives of your tyres

Although tyres are designed to wear out, there is no point in having the tread wear out sooner than they have to. The more wheels are misaligned, the quicker tyres wear out.

In practice, severe misalignment can reduce tyre life by as much as 60% or more, which makes no sense from a financial standpoint.

You improve your car’s handling

When a car’s front and rear wheels are properly aligned, the steering will always be precise and predictable, and maintaining control of the car will always be easy.

However, when the wheels are not aligned, steering responses may be sluggish, or the vehicle may “wander” across the road without any steering inputs. Moreover, misaligned wheels can cause the vehicle to pull sharply to one side under braking, which can be dangerous in emergencies.

You ensure all safety systems work as they should

Safety systems like Stability Control, Traction Control, Roll-Over Warning, and even Park Assist all need to “know” where the front wheels are pointing to work correctly. These systems obtain his data from the steering angle sensor, which is referenced to the wheel alignment.

Thus, if the wheel alignment is not correct, the steering angle sensor cannot relay valid input data to other control modules. In practice, this means that one or more safety systems might stop working when the wheel alignment is not correct.

Can a wheel alignment be done wrong?

While it is extremely rare for professional technicians to get a wheel alignment wrong, it can happen. Here are some examples of things that can go wrong-

Defective parts go undetected

Technicians sometimes work under extreme time constraints. Therefore, it is possible for a wheel alignment technician to miss a worn ball joint, worn tie-rod end, or worn control arm bushings during an inspection.

Wheel targets are placed wrong

Wheel targets are usually mounted to the rim, but in rare cases, the target is clamped around the tyre. In these systems, it is possible to misalign a target.

Failure to check steering sensor calibration

Some kinds of suspension and steering system repairs require that the steering angle sensor be recalibrated, which is a hugely important step in these repair procedures.

The function of the steering angle sensor is to monitor the angle and direction of steering inputs. This information is used by safety systems like Stability Control, Traction Control, Automatic Emergency Braking, and others to help the driver maintain control of the vehicle in some situations.

Incorrect input data is used

The most important part of any wheel alignment service set-up procedure is to enter the correct vehicle make and model into the system. However, wheel alignment equipment cannot “recognize” the car being worked on. Therefore, when the wrong vehicle details are entered into the system, a technician might make adjustments based on wheel alignment settings that do not apply to the vehicle being worked on.

The most important thing to remember is that technicians and mechanics are human, and all humans can make mistakes. However, most wheel alignment services include a test drive to verify the proper alignment of the wheels. In practice, this means that the effects of mistakes made will be recognised, and corrected immediately.

How long does a wheel alignment take?

How long a wheel alignment takes depends on the vehicle, and whether (or not) additional work is required.

Nonetheless, a simple front wheel alignment should not take longer than about 30 minutes or so. More difficult alignment procedures, such as 4-wheel alignments on vehicles with multi-link rear suspension systems can take about an hour.

Bear in mind though that the above time estimates only apply to wheel alignment services that do not require the replacement of worn or damaged steering or suspension parts. In these cases, the time required depends on the vehicle, as well as on the actual parts that need to be replaced.

Therefore, we highly recommend that you visit Find a Mechanic before you take your car anywhere for a wheel alignment and balancing service. Here you can find professional workshops and tyre service establishments near you that can give you accurate price and time estimates that include all relevant costs and charges before you make a booking.

How much does a wheel alignment cost?

Today, it is rare to find tyre fitment centres and workshops that do not do 4-wheel alignments as a matter of course on all vehicles. In fact, most, if not all car manufacturers prescribe 4-wheel alignments as a requirement on all their products.

However, a 4-wheel alignment price depends on the vehicle, as well as on where you live in the country. For instance, a wheel alignment procedure for a small compact car might cost only about $50, while a wheel alignment procedure for a high-end luxury vehicle could run to about $200 or so. Note that any additional work such as replacing worn, damaged, or broken parts will incur additional charges.

Wheel balancing

On most vehicles, balancing all four wheels should not cost more than about $50 or so. However, many tyre fitment centres and workshops include the cost of wheel balancing as part of a wheel alignment procedure. This means you could get the wheel balancing free.

To get the best possible service and price on your wheel alignment, we suggest that you Find a Mechanic to find professional wheel alignment technicians and tyre fitment centres near you.